A Short History of Kiln-Cast Glass

From Sam Herman’s pioneering studios to the kiln-formed works of Keith Cummings, Colin Reid and Fiaz Elson — explore the evolving story of cast glass in Britain.

Glass has always carried light across human history — from the stained windows of cathedrals to the prisms of science. But it is only within the last sixty years that glass has been freed from industry to become a fully personal medium of sculpture and expression.

Sam Herman, Untitled, blown glass, signed and dated 2013, 37cm (14.5in) high, Private Collection

Photographe: © Sylvain Deleu 2018

From Factory to Studio

The studio-glass movement began in the early 1960s when artists such as Harvey Littleton and Dominick Labino demonstrated that molten glass could be melted and formed outside a factory. Their 1962 workshops in Toledo, Ohio, gave birth to the idea of artist-as-glassmaker.

In Britain, that idea took root through Sam Herman, an American artist who studied under Littleton and moved to London in 1966. At the Royal College of Art, Herman founded The Glass House in Covent Garden (1969), where artists could blow, fuse and cast their own work. His example ignited a generation — yet it was only one of many seeds.

While Herman’s furnaces burned bright, other artists were quietly exploring glass in the kiln, where heat works slowly and gravity becomes a collaborator.

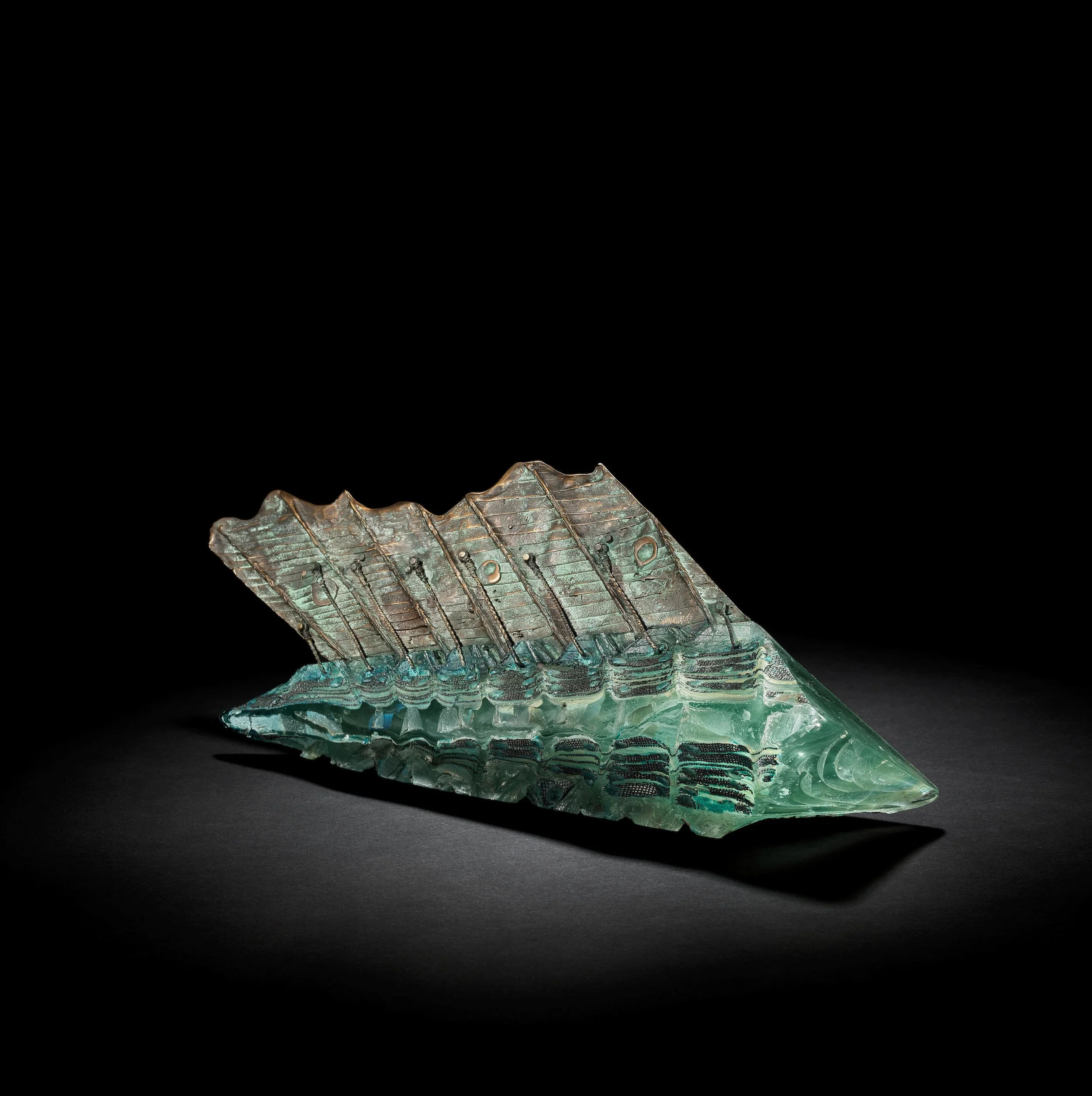

Keith Cummings 'Flagship', sculpture, 1991

The Language of the Kiln

The shift from blowing to kiln-forming opened new possibilities: fusing sheets, slumping over moulds, or casting molten glass into refractory forms. This quieter revolution drew on ancient techniques but was renewed by twentieth-century research.

In Britain, Professor Keith Cummings at Wolverhampton University became a key figure in this evolution. Through decades of teaching and writing — notably A History of Glassforming and Techniques of Kiln-Formed Glass — he mapped the ways temperature, time and material can be used as creative partners.

Cummings’ own pieces, such as Watercolour and Red Stack, combine architectural precision with painterly sensitivity. Many of today’s artists, in the UK and abroad, acknowledge his influence in understanding how glass can hold both structure and spirit.

‘Still Life With Corn’ Colin Reid 2017

Optical Sculpture and the Language of Light

Among those inspired by Cummings’ teaching was Colin Reid, who, from his studio in Stroud, pioneered the use of optical kiln-cast glass. Reid’s work involves building complex moulds, casting crystal-clear glass, and then grinding and polishing the surfaces to reveal internal landscapes of reflection and shadow.

His sculptures, such as Gatekeeper and Loch Moidart, are collected by museums around the world, including the Victoria and Albert Museum and the Metropolitan Museum of Art. Reid’s practice showed that cast glass could be as monumental, precise and emotionally resonant as bronze or stone.

But he is one voice among many. Over the same decades, artists across Britain — from David Reekie to Angela Thwaites, Joseph Harrington to Cathryn Shilling — developed their own vocabularies, proving that kiln-formed glass is a plural art, not a single lineage.

Alongside them stand countless other makers — teachers, technicians, experimenters — whose furnaces and kilns together form the living ecology of glass in Britain.

Kiln-cast glass, at its heart, remains a shared endeavour: a conversation between fire, material and imagination. Continuing the Conversation

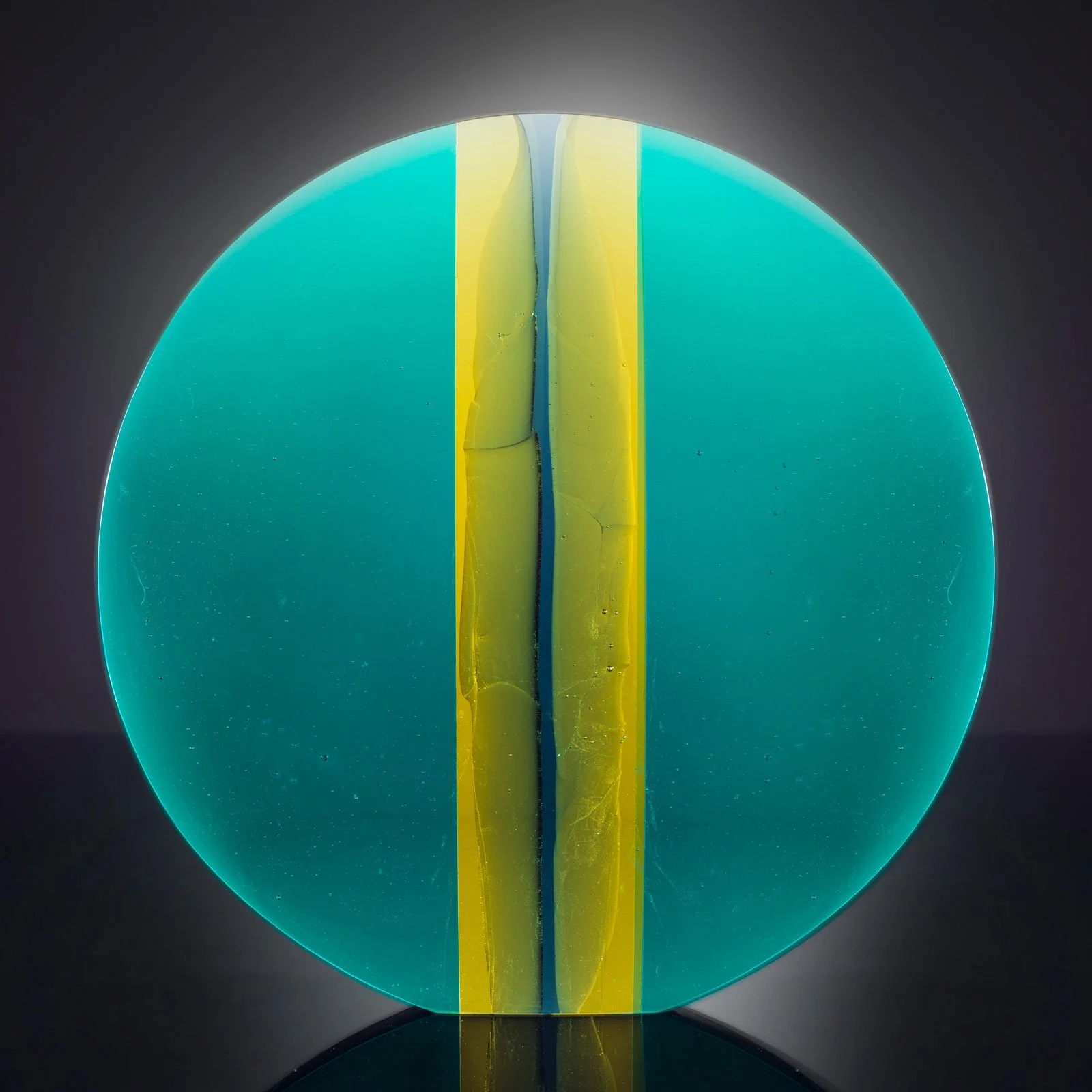

Fiaz Elson, Creative Director of The Glass Foundry and former senior assistant to Colin Reid, represents the next movement in this conversation rather than a conclusion to it.

Her practice explores the interplay between strength and delicacy, transparency and concealment — themes shared by many contemporary glass artists. Works such as Osiris and Rheiopolis balance disciplined technique with an intuitive sense of emotion and form.

At The Glass Foundry, Elson collaborates with artists, designers and architects to test new ideas in casting, colour and light. The studio’s ethos is one of continuity through openness: honouring those who came before while inviting others to shape what comes next.

Ocean - Fiaz Elson 2022

Turning Glass into Light: The Art of Kiln Casting

See how kiln casting glass turns raw shapes into polished features for buildings, boats, or galleries, layered, textured, and made to last.

Kiln casting glass takes something cold and rigid, like raw glass, and transforms it into something full of shape, light, and detail. The process begins with placing the glass into a custom mould and slowly heating it in a kiln until it softens and flows into its final form. What starts as crushed or chunky glass ends up as a smooth, solid piece that's often part of something bigger, like a wall, a sculpture, or a feature in a hotel or yacht.

We’ve seen how this method allows ideas to become physical forms that feel both precise and expressive. Whether used in small details or large installations, kiln casting opens up a path between structure and creativity. Each stage, from shaping the mould to the cooling of the glass, plays a role in that transformation. This is how raw materials become thoughtful centrepieces.

Mould Making: Shaping the Idea

Before glass ever sees the heat of a kiln, we need a mould that can hold the idea in place. Everything begins with a pattern, shaped by hand in soft materials like clay, wax, or foam. These hand-built forms give us total control over shape, texture, and line.

Once the pattern is ready, we build the mould around it layer by layer. We usually use plaster mixed with fine silica. This blend picks up every detail, from gentle curves to sharp cuts. The process might take several steps:

1. Apply a smooth base coat to catch surface detail

2. Build up extra thickness for strength

3. Let everything dry thoroughly

Once the mould sets, we remove the original pattern from inside. What’s left is a hollow space that matches it exactly. This becomes the shape the glass will take on.

The Casting Process: From Granules to Glimmer

rNow that we have our mould, it’s time to begin the real magic. Glass pieces or granules are loaded into the space above or inside the mould. We place the whole setup inside a specialised kiln and slowly raise the temperature until the glass becomes soft and starts to settle into shape.

Timing and temperature matter a great deal here. One degree off and you might have bubbles where you don’t want them, or the glass may shift unevenly. Done with care, though, you end up with a strong piece that holds its look and doesn't crack under pressure.

Kiln casting glass also lets us play with effects like:

• Controlled bubbles that add pattern or contrast

• Coloured frit added to form gradients or details

• Layers that offer depth and variation through the thickness

The glass flows slowly and settles entirely into the mould, taking on every curve and edge designed at the start. Once it’s in place, we allow it to cool at a careful pace.

Detailed Finishing: Bringing Out the Character

After the casting comes patience. Cooling the glass isn’t a quick stage. Depending on the size and shape, we might leave it to settle for several days or even weeks. This slow cooling helps prevent stress and makes sure the piece won’t crack later on.

When it’s fully cooled and solid, we remove the mould. Then the finishing work begins.

• We sand rough edges to make them safe and clean

• The surface gets polished to catch and reflect light

• Sometimes we lightly engrave areas for added depth or to work with shadows

Each touch helps tie the piece into its final setting. Whether it's part of a larger piece or stands on its own, we check by hand to make sure it fits just right with whatever structure it belongs to.

Fitting Glass into Architectural Design

Kiln-cast glass has the flexibility to match many different design styles. We've seen it used in bold, modern buildings with sharp lines as well as in restored settings with more traditional features. Its balance of strength and clarity means it often appears where other materials may not work as well.

Popular uses in architecture include:

• Wall panels in hallways or lift lobbies

• Floors with textured grip and light-catching layers

• Water features that use glass for both structure and sound

• Entrances or feature walls in hotels or galleries

• Public artworks that blend into outdoor spaces

At The Glass Foundry, our studio in the Cotswolds is designed to handle large architectural commissions, from substantial glass panels for hotels to specialist pieces for cruise ships and public spaces. Since we make our own moulds, our team can shape bespoke features for both interior and exterior installations with precision.

The beauty of kiln casting glass is that it doesn't force designers or clients to choose between shape and toughness. You can have panels that hold up to heavy use but still feel expressive.

Why Autumn Is the Perfect Time to Plan Custom Glass Features

As autumn settles in and the days grow shorter, the way light moves through spaces begins to shift. Indoors, that can change how we use colour, reflection, and texture. Outdoors, softer sunlight and lower angles can make glass glow in ways it doesn’t during high summer.

Planning around October lets us take that slower seasonal mood into account. The casting process needs careful thinking, from idea through to design and cooling. Giving more time means the finished work is ready for winter display or early-year installations. It’s a season that naturally supports deeper creative focus.

There’s a calmness that comes with autumn. It allows ideas to breathe, and casting schedules often move at a steadier pace, which matches well with the overall timing of kiln-fired work.

Legacy in Glass: Cast Pieces That Last

Every cast piece we finish carries the trace of thought, effort, and hands-on work. Nothing is made fast or by accident. The final surface holds light in ways that change as the day shifts, and that makes each piece part of its setting rather than separate from it.

With roots in fine art glass and architectural commissions, we’re proud our studio produces glass for museums, awards events, and even television productions. No matter the project, kiln casting glass lets us create pieces that are built to endure and designed to enrich.

At The Glass Foundry, we work closely with artists, architects, and designers to shape ideas into lasting pieces that bring clarity and depth to any space. When your next project calls for something tactile, light-filled, and built to last, our approach to kiln casting glass focuses on both technique and collaboration. Whether you’re looking for a large-scale installation or a small architectural detail, we cast with purpose and precision here in the Cotswolds. Let’s talk about creating something that fits just right, get in touch today.